Note:

working with high voltage and batteries is dangerous and can be

lethal. Those involved with this project are trained in high

voltage safety and battery safety, and the depth of their

involvement depends on their level of engineering expertise. Do

not involve yourself in a similar project unless you are qualified and

are aware of the safety precautions that must be taken. Always

take appropriate precautions: even training and expertise does

not eliminate the possibility of injury or death.

Here we go!

The chassis comes from a Birkin S-3 car kit.

<>

Crated Chassis

The kit comes with most of the parts needed to

assemble the car.

It is designed to be powered by a four cylinder gasoline engine, one of

the main items not included with the kit.

Kit Parts

The car will instead be propelled by an electric

Motor powered by rechargeable Batteries.

The motor is a 3-phase AC induction Motor, which can

convert over 100 horsepower of electrical power into wheel turning

mechanical power.

Motor

The torque and speed of the Motor is controlled by

the Motor Controller, which converts DC Battery electricity into

3-phase AC electricity to power the Motor.

The Motor Controller constantly adjusts the way this

electrical power is delivered

to the Motor,

based on the position of the Accelerator Pedal.

Additionally, the Motor Controller has a built-in

DC-to-DC Converter for charging the car's

on-board 12 Volt car battery. This 12 Volt car

battery powers the lights,

windshield wipers, and other traditional automotive

electrical accessories.

Motor Controller

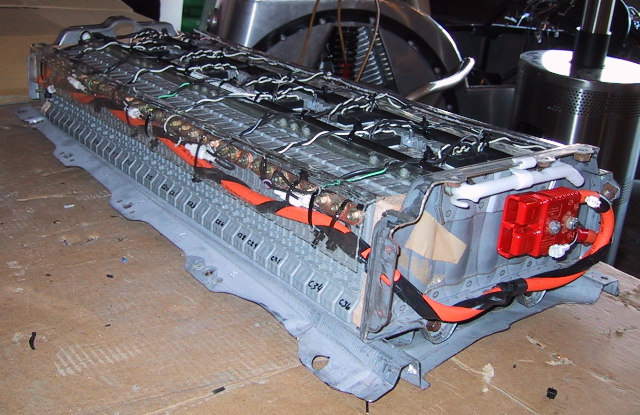

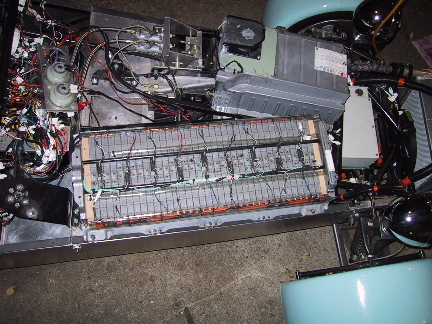

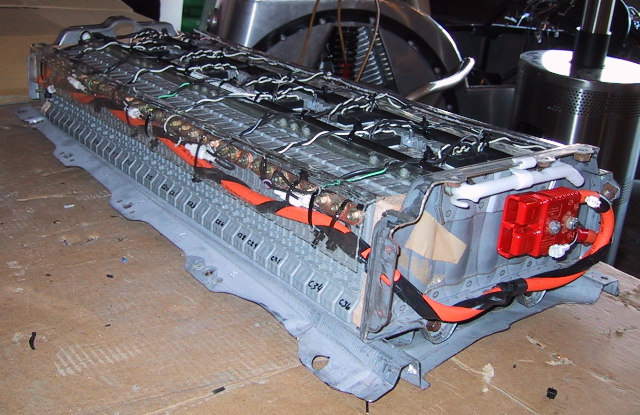

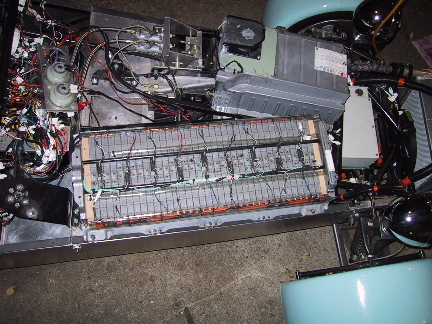

152 NiMH battery modules provide power to the Motor

Controller. These battery modules were removed from

hybrid-electric cars found in salvage yards.

NiMH Battery Modules

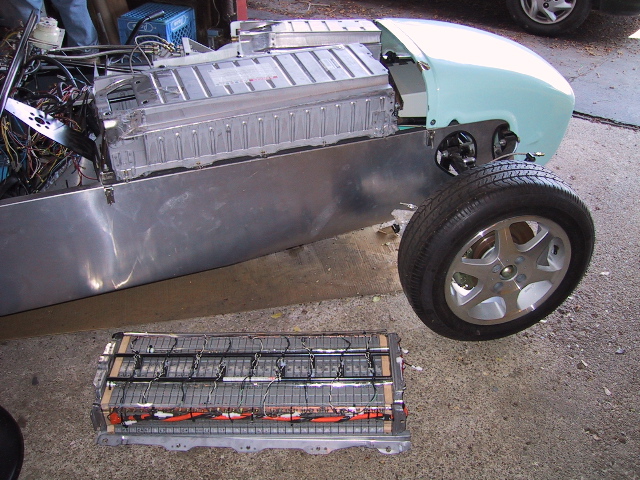

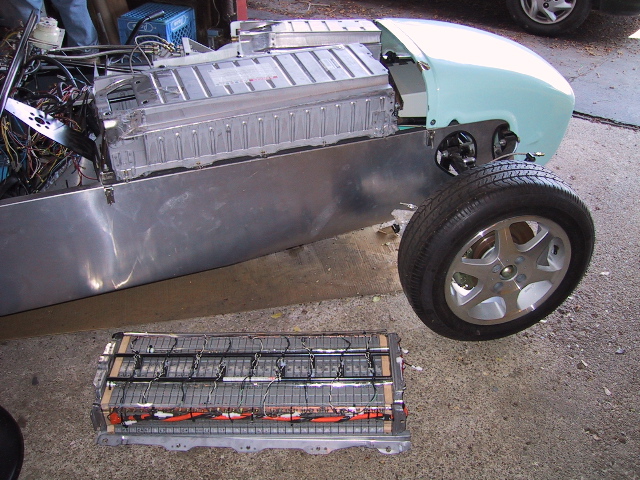

The hybrid-electric car battery packs were combined

and re-engineered to provide four times the original capacity and

power.

The original battery module enclosures were modified and re-used in the

creation of the Battery Assemblies.

Battery Assembly

A total of five custom Battery Assemblies will power

the vehicle.

The five Battery Assemblies.

The original Birkin S-3 kit requires assembly and modification to make

the electric7 a reality.

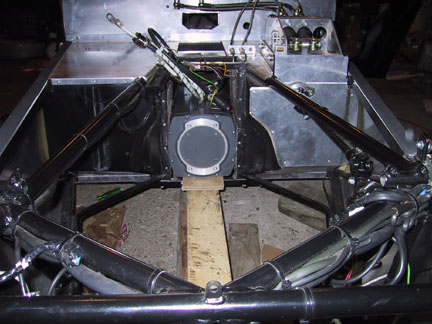

The Chassis is seen here with Suspension and

Wheels installed.

Chassis with Suspension, Steering, Wheels, and Tires.

Special low rolling resistance Tires have been selected, a type

designed for GM's EV1 electric car.

Their design extends driving range, and their

self-sealing capability

allows the spare tire to be left behind, saving weight.

Low rolling resistance, self-sealing Tires.

Light-weight aluminum Wheels were chosen to complement the Tires.

Is the "E" for Electric?

Aluminum wheel with tire mounted.

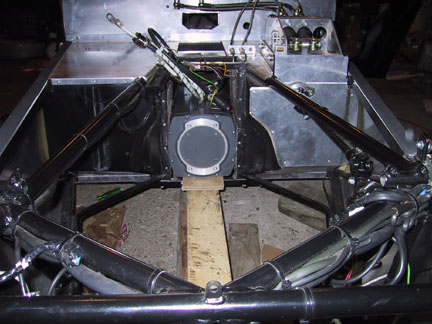

The Motor fits into the Chassis's transmission tunnel.

Motor in transmission tunnel.

This leaves engine compartment space available to

mount Battery Assemblies and the Motor Controller.

Engine compartment space with Motor in transmission tunnel.

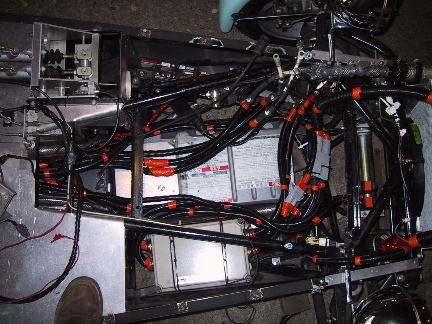

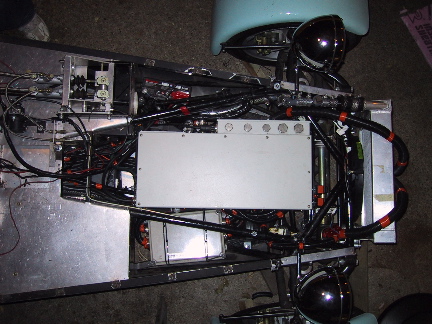

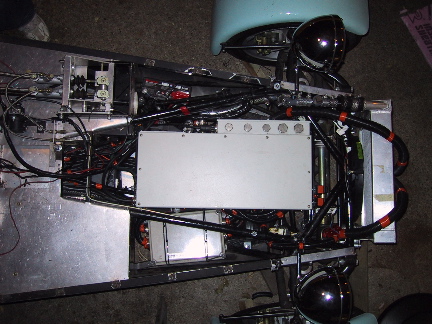

In the engine compartment area, three Battery

Assemblies are installed, along with the Motor Controller. The

top two Battery Assemblies (shown incomplete) are in their design

intent locations. The Motor Controller is visible beneath these

Battery Assemblies, and a third Battery Assembly is located below the

Motor Controller.

Front Battery Assemblies and Motor Controller.

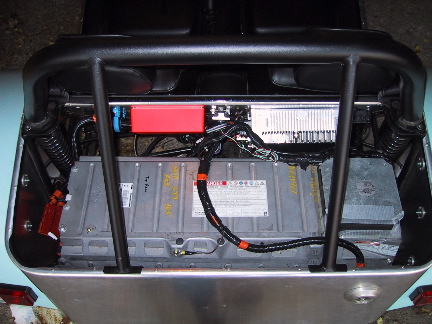

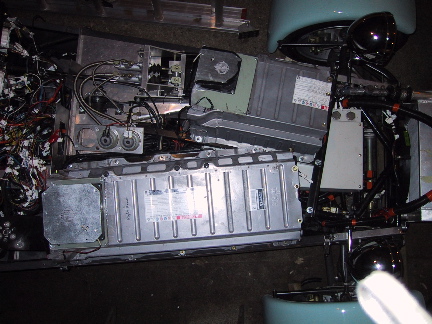

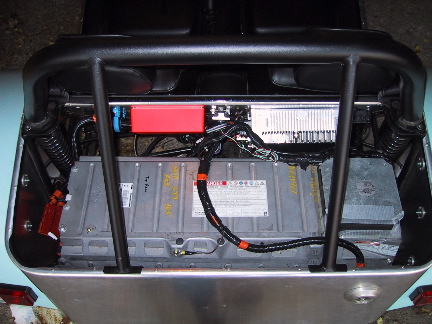

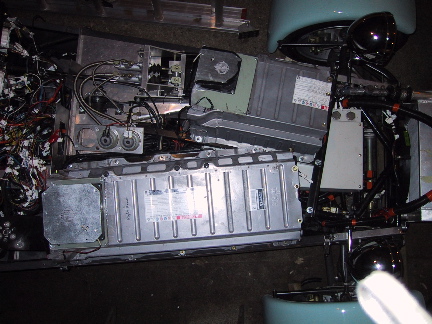

The other two Battery Assemblies are located in the rear of the car,

along with the Battery Charger.

Rear Battery Assemblies and Battery Charger.

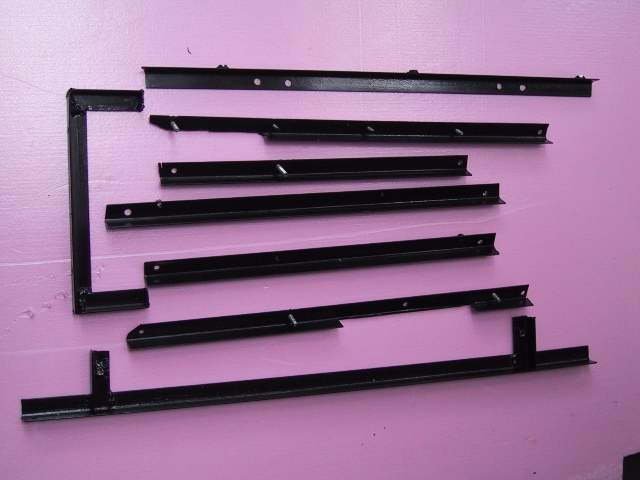

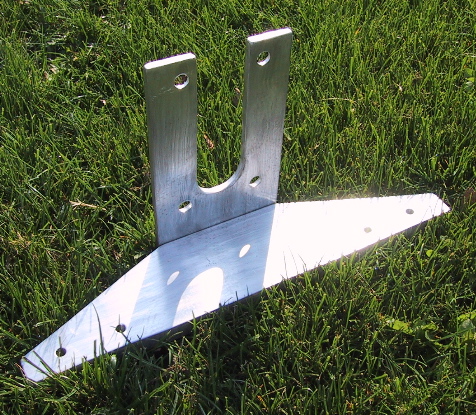

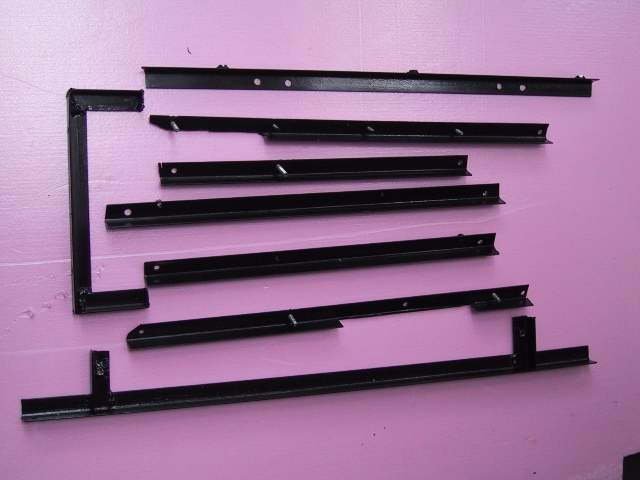

The mounting of the Battery Assemblies and Motor

Controller require a number of custom-made Mounting Brackets.

Custom-made Mounting Brackets.

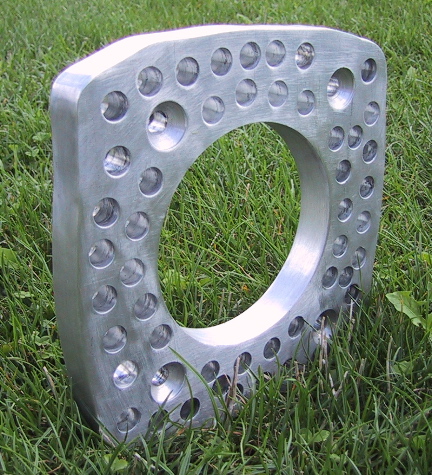

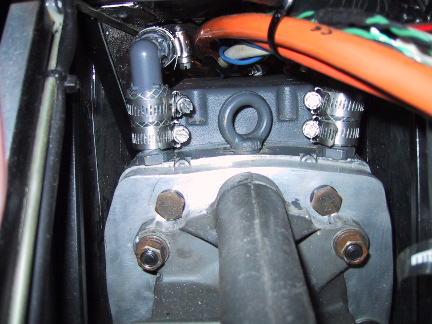

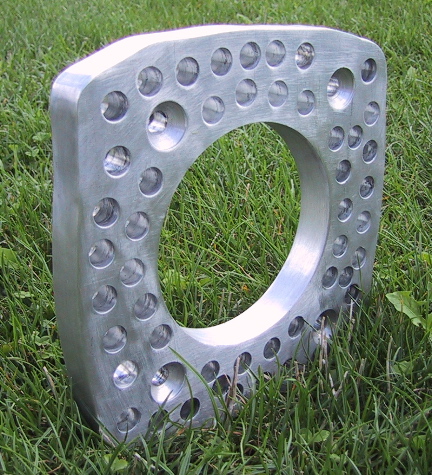

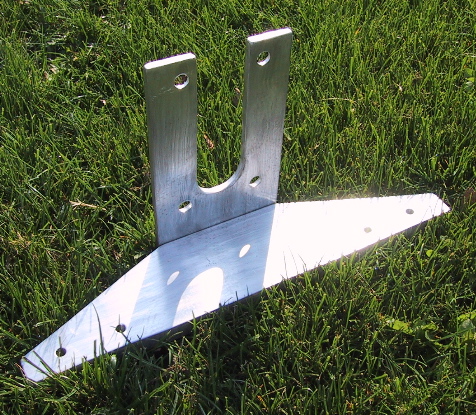

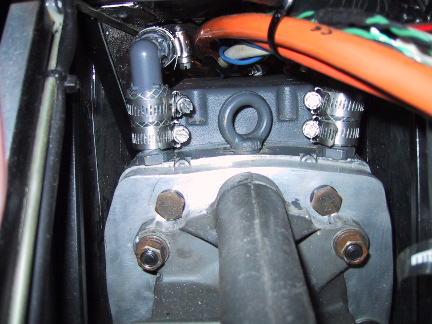

The Motor requires a custom Adapter Plate and Motor-to-Chassis Mount.

Motor Adapter Plate and Motor-to-Chassis Mount.

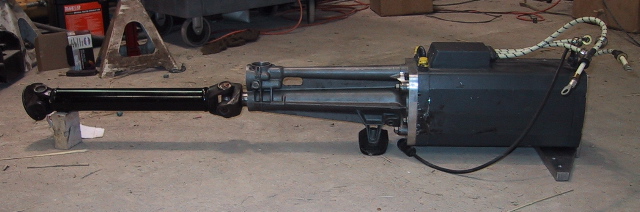

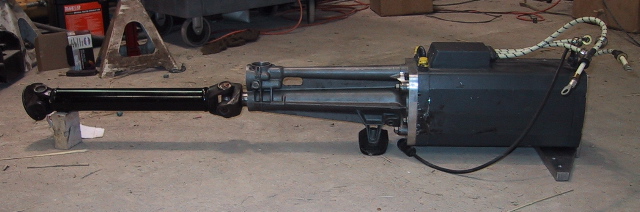

A custom-splined Intermediate Shaft bridges the gap

between the Motor and the Drive Shaft.

Intermediate Shaft with Bearing

The Adapter Plate and Motor-to-Chassis Mount attach

directly to the Motor, and allow the Motor to be connected to the Drive

Shaft Carrier. The Drive Shaft Carrier also attaches to the

vehicle Chassis, but its main purpose is to couple to Motor to the

Drive Shaft, which turns the wheels through the rear Live Axle.

Powertrain assembly.

It is congested, but the Motor is shown installed with

the Motor-to-Chassis Mount.

Mounted Motor.

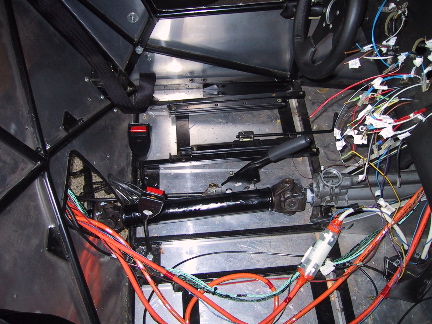

With the Powertrain fully installed, the Driveshaft

can be seen connecting the Live Axle to the Intermediate Shaft, which

gets turned by the Motor.

Assembled Drivetrain.

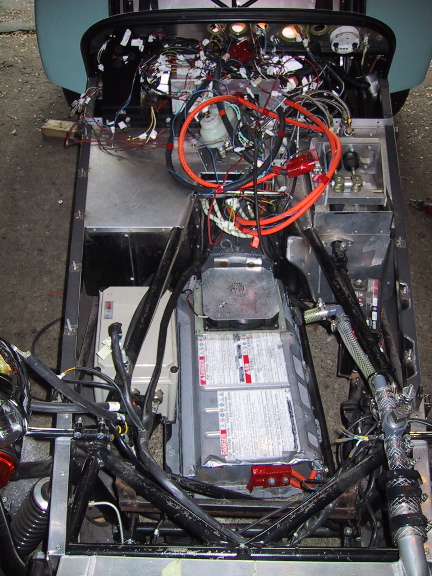

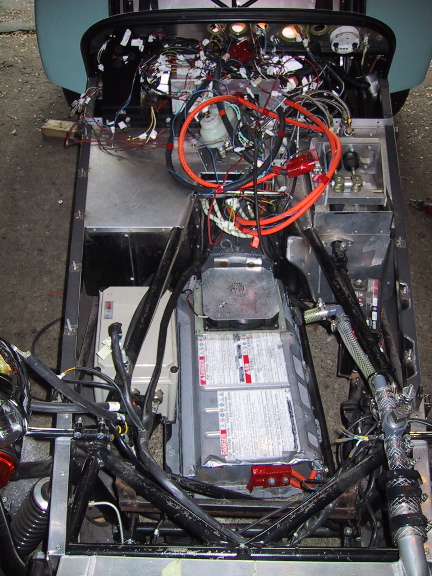

With the the Motor installed, the front lower

Battery Assembly gets bolted into position. The 12V Lead Acid

Battery and the Contactor Box are also attached on their welded-in

Bracketry.

Lower Battery Assembly with Contactor Box and 12V Lead Acid Battery.

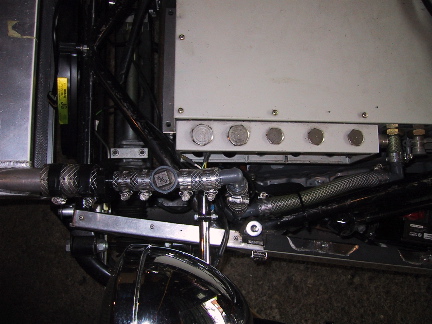

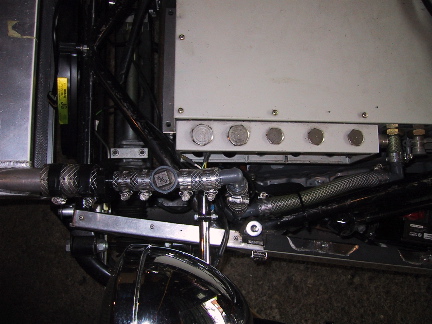

A custom-made cooling manifold connects the radiator to the Motor

Controller. Both the Motor Controller and the Motor are cooled by

regular antifreeze.

Cooling manifold connects radiator to Motor Controller.

The other end of the cooling manifold connects to the Motor.

Antifreeze gets circulated through the Motor and the Motor Controller

by an electric pump.

Two cooling hoses connect to the top of the Motor.

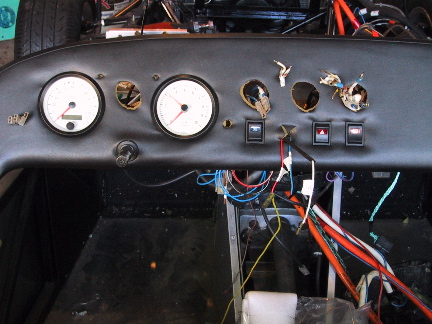

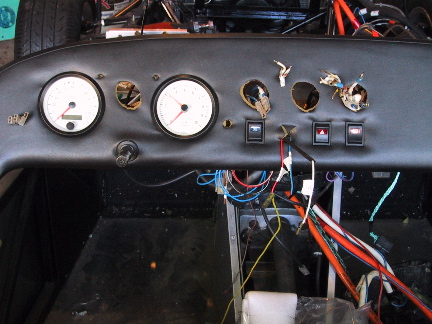

With some modifications made to the instrument panel

to accommodate their size, a Speedometer and a 10,000 RPM Tachometer

are

installed. Also shown is the headlight switch, hazard switch, and

heated windshield switch. The windshield wiper switch is ready to

be installed.

Instrument panel coming together.

All of the Instruments are now installed into the

Dashboard!

From left to right: Speedometer, State of Charge Gage,

Tachometer, 12V Battery Voltmeter, Propulsion Battery Ammeter (-100 to

+300 amps), Propulsion Battery Voltmeter (200 to 400 Volts).

Also, from left to right, Horn Button, Turning

Signal Switch, Low Brake Fluid Light (red), Turning Signal Indicator

Light (green), High Beam Switch Button, TBD Light (orange), and High

Beam Indicator Light (blue).

Dashboard complete with Instruments.

The next goal is to get the car ready for an

initial test drive. The center console, seats, and seatbelts are

bolted in and are ready for the drive. Carpeting and other

upholstery can be installed later. The steering wheel will be

installed once the tachometer tests out OK.

Cockpit with seats, shoulder belts, and center console bolted in.

Here is another view of the cockpit seating.

Note that the rollbar is installed behind the headrests.

Seating area.

The rear compartment is ready for the first test

drive. Wiring is protected by convoluted tubing and is

restrained. Screens have been installed on battery pack air

inlets to limit debris entry. The 12V fan power supply has been

tested to power the battery fans when the 220V AC plug is connected.

Rear compartment, viewed from the top rear.

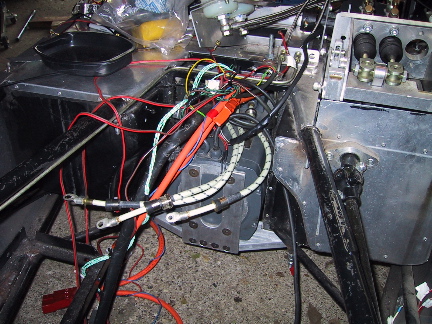

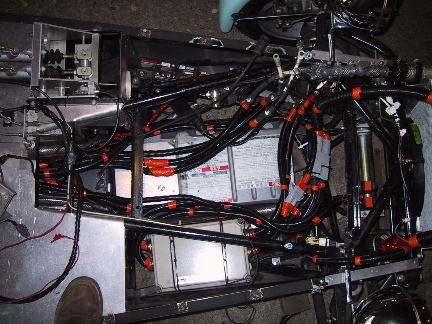

Most of the pre-test drive work remaining is in the

front section. Wiring has been put in convoluted tubing for

protection and is being routed. Above the front lower battery

pack, the

inverter can be installed.

Front compartment, viewed from the top right.

With wires routed, the inverter is bolted in place

to brackets above the front lower battery pack. Coolant fittings

are mated. Both power and signal electrical connections have been

made.

Inverter installed above front lower battery pack.

With specific modifications to allow its battery cooling fan to fit

under the hood of the car, the front left battery pack is installed on

its bracketry. It sits above the inverter, which sits above the

front lower battery pack, resulting in three layers of hardware in the

front section.

Left front battery pack installed above inverter.

The front right battery

pack sits on its mounting points, awaiting installation of its

cover. Once its cover is installed, the fan control and

temperature sensor wiring will be connected and the battery system

installation will be tested.

Right front pack partially installed without its cover.

The front right battery

pack's cover is now installed with its fan and temperature sensor

wiring hooked up. The next step will be to retest the battery

system by powering the inverter and performing a wheel spin test.

Both front top battery packs installed.

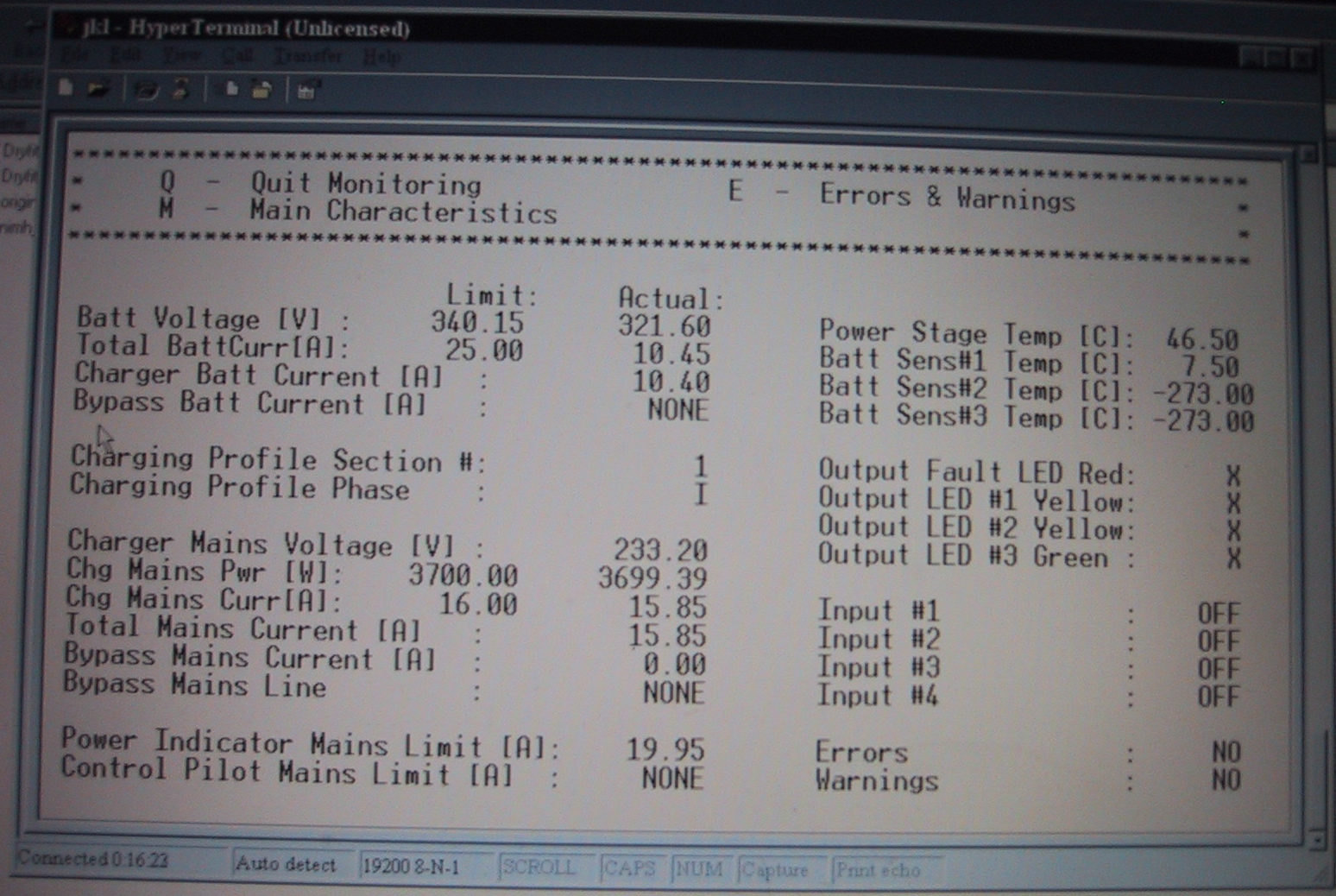

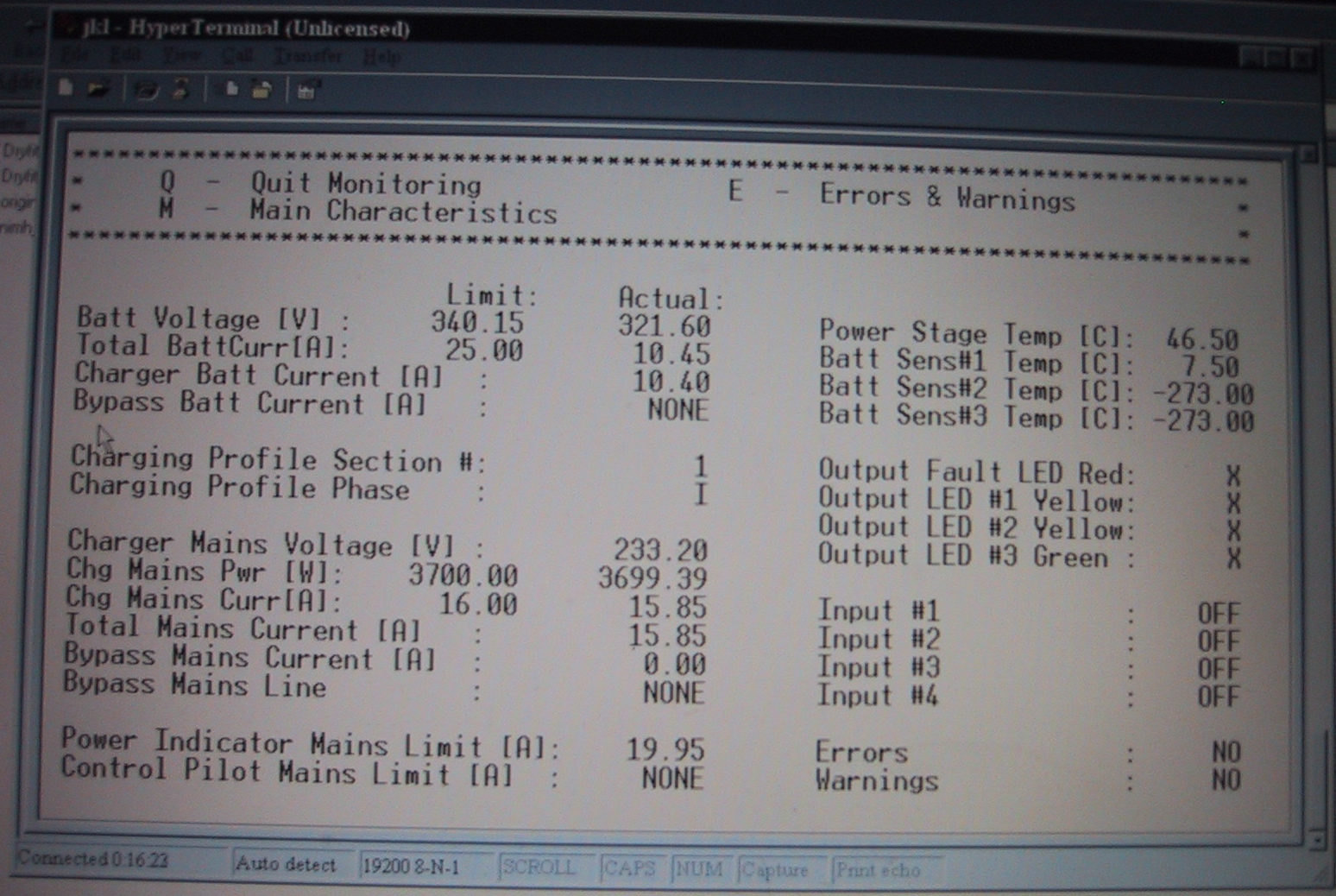

Charging!

First charge monitor data.

With the help of an old laptop computer, the

charger was programmed and has now charged the batteries with 3.3 kW of

electrical power! Check out the photograph of the charger monitor

screen.

First Driving Test

On January 8, 2005, we drove the car down and back up the driveway on

its own power six times! Click on the image below to download and

watch the video of Steve driving the car! The

hood, windshield, and nosecone were not installed for this test.

Steve drives the car up the driveway! (Click on image to watch

the Quicktime movie.)